Custom springs drive precision in modern technology

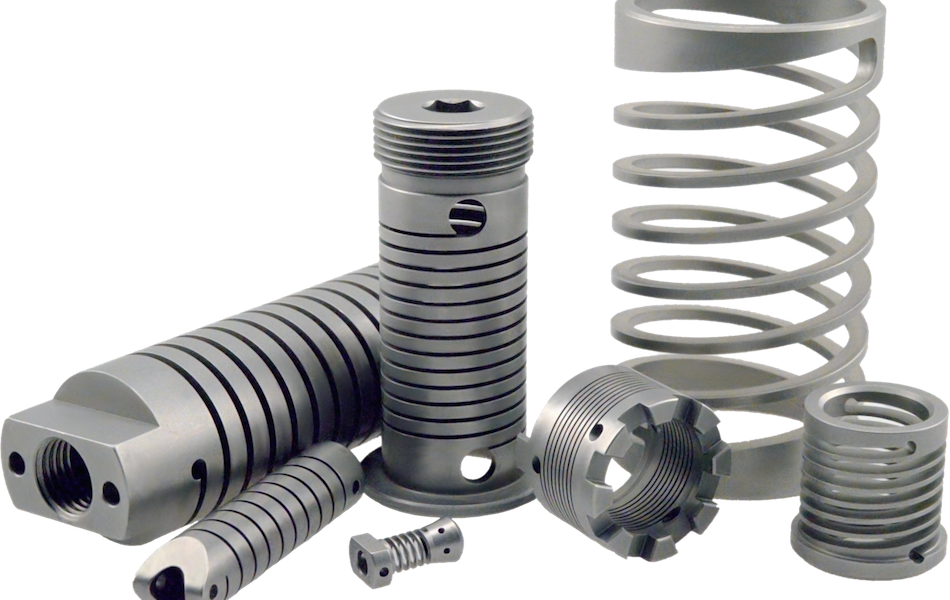

Springs represent one of the most versatile mechanical components across countless technological applications. While standard springs serve many purposes, custom springs have become indispensable in specialized equipment where exact specifications matter. These tailored components meet unique requirements that off-the-shelf alternatives simply cannot fulfill. From medical devices requiring specific force characteristics to aerospace applications demanding precise tolerances, customised configurations allow engineers to optimize performance for their exact needs. Tension springs, compression springs, and torsion springs can all be manufactured to exacting standards, with variables like wire diameter, coil count, and material composition adjusted to match particular demands. The ability to specify every aspect of a spring’s design ensures that technology performs reliably under specific conditions. Whether supporting delicate mechanisms in precision instruments or withstanding extreme environments in industrial machinery, these specially engineered components provide solutions where generic options fall short. Understanding how custom springs enhance technological capabilities reveals their significance in modern engineering.

Tailored specifications meet complex engineering demands

Custom springs solve problems that standard components cannot address. Engineers working on specialized projects often face requirements that fall outside typical manufacturing parameters. A medical device might need a spring that delivers consistent force across thousands of cycles while fitting within millimeter-scale constraints. An automotive application could require springs that maintain performance across extreme temperature ranges. These scenarios demand precision that only customised configurations can provide.

Manufacturing custom springs begins with detailed specifications. Engineers must consider the operating environment, expected load cycles, space limitations, and performance characteristics. Material selection plays a vital role, as different alloys offer varying properties regarding strength, corrosion resistance, and temperature tolerance. Stainless steel works well for medical and food processing equipment, while music wire provides excellent fatigue resistance for high-cycle applications. The wire diameter, coil diameter, and number of coils all influence how a spring behaves under load.

Tension springs illustrate the importance of customization particularly well. These springs, which operate by stretching rather than compressing, require precise initial tension and hook configurations. The hooks or loops at each end must accommodate specific mounting points while maintaining strength. A poorly designed hook can become the weakest point in an otherwise robust spring. Custom manufacturing ensures these critical details receive proper attention, resulting in components that perform reliably within their intended systems.

Clockwork springs power mechanical precision

Clockwork springs demonstrate how specialized spring design enables complex mechanical systems. These tightly wound springs store energy through rotation, releasing it gradually to power mechanisms. Traditional timepieces relied entirely on clockwork springs to maintain accurate timekeeping, with the spring’s unwinding providing consistent force to drive gears and escapements. Modern applications extend far beyond clocks, though the fundamental principles remain unchanged.

The design of clockwork springs requires careful attention to material properties and dimensional accuracy. These springs typically use flat ribbon-like wire wound into tight spirals, with the material needing to withstand repeated winding cycles without losing elasticity. The thickness and width of the ribbon affect how much energy the spring can store and how quickly it releases that energy. A music box uses a relatively simple clockwork spring that unwinds over minutes, while precision instruments might require springs that maintain consistent force output across their entire operating range. Custom clockwork springs appear in unexpected places throughout modern technology.

Retractable cables in electronic devices use spring mechanisms similar to clock springs. Some safety equipment relies on clockwork springs to provide mechanical backup when electrical systems fail. Measuring instruments sometimes incorporate these springs to create predictable, repeatable motion. The ability to customize the spring’s dimensions, material, and force characteristics allows designers to integrate these components into systems where space is limited and reliability is paramount. Each application benefits from springs engineered to exact specifications rather than adapted from standard designs.

Material selection shapes spring performance

The materials used in custom springs directly impact their performance characteristics and lifespan. Different applications demand different material properties, making material selection one of the most critical decisions in spring design. Stainless steel varieties resist corrosion and work well in wet or chemically aggressive environments, making them popular for medical equipment and food processing machinery. Carbon steel provides excellent strength and fatigue resistance at lower costs, suitable for many industrial applications. Specialized alloys like Inconel withstand extreme temperatures, while beryllium copper combines electrical conductivity with spring properties.

Heat treatment processes modify material characteristics further. Springs can be tempered to increase hardness and strength, or stress-relieved to improve dimensional stability. These processes allow manufacturers to fine-tune spring behavior even after forming. A tension spring destined for high-cycle applications might undergo specific heat treatments to maximize fatigue life, while a spring requiring precise force characteristics could receive treatments that stabilize its properties across temperature variations. Surface treatments add another layer of customization.

Zinc plating protects against corrosion in moderately harsh environments. Powder coating provides both protection and visual identification in assemblies with multiple spring types. Passivation enhances the natural corrosion resistance of stainless steel. Shot peening compresses the spring’s surface, creating residual stresses that improve fatigue resistance. Engineers specify these treatments based on operating conditions, with customised configurations incorporating whatever combination of materials and treatments best serves the application. The interaction between base material, heat treatment, and surface finish creates springs optimized for specific technological demands. This level of control over material properties separates custom springs from standard catalog items that must compromise to serve broader markets.

Industries relying on custom spring solutions

Custom springs support critical functions across numerous technological sectors. The versatility of these components means they appear in applications ranging from consumer electronics to heavy industrial equipment. Each industry presents unique challenges that require tailored spring solutions rather than generic alternatives.

Medical technology depends heavily on precision springs. Surgical instruments need springs that provide tactile feedback to surgeons while maintaining sterility standards. Implantable devices may incorporate tiny springs manufactured from biocompatible materials. Diagnostic equipment uses springs calibrated to exact force specifications, ensuring consistent and accurate results. The regulatory requirements in medical applications demand documentation and quality control that custom manufacturers can provide.

Aerospace and defense applications push spring technology to its limits. Components must function reliably across extreme temperature ranges, from the cold of high altitude to the heat of engine compartments. Vibration resistance becomes paramount in aircraft and vehicles. Weight considerations drive engineers toward springs that deliver required performance with minimal mass.

Electronics manufacturing relies on various spring types:

- Battery contacts using compression springs with specific conductivity requirements

- Tension springs in retractable cord mechanisms for headphones and charging cables

- Torsion springs providing resistance in hinges for laptops and tablets

- Clockwork springs in camera shutters and mechanical timers

- Micro-springs in switches requiring millions of operation cycles

Automotive systems incorporate custom springs throughout vehicle designs. Valve springs in engines must withstand high temperatures and rapid cycling. Seat mechanisms use multiple spring types to provide comfort and adjustment capabilities. Safety systems like seatbelt retractors depend on springs engineered for reliable emergency response.

The role of custom springs, such as customised configurations of tension springs in technology continues to expand as devices become more sophisticated and specialized. Engineers increasingly recognize that generic components cannot meet the precise requirements of modern applications. Customised configurations allow for optimization across multiple parameters simultaneously, whether that means a tension spring with specific hook geometry or a clockwork spring with exact energy storage characteristics. The ability to specify materials, dimensions, and treatments down to minute details enables technological advances that would otherwise remain impossible.

Manufacturing capabilities have evolved to support even the most demanding specifications. Precision equipment produces springs with tolerances measured in fractions of millimeters, while quality control processes verify that each component meets its design parameters. This combination of engineering expertise and manufacturing precision ensures that custom springs perform their intended functions reliably. From the smallest medical device to large industrial machinery, these specially engineered components enable technology to function as designed. The attention to detail in custom spring manufacturing reflects the broader trend toward precision engineering, where every component receives the consideration necessary to achieve optimal system performance.